Description

SMART series intelligent bulk moisture analyzer can be applied to measure the moisture content in most solids, which helps to control product quality and cost (dryer, water, energy, weight, etc.) according to material moisture.

Working Principle

The capacitance field sensor generates electromagnetic waves (frequency of about 30 MHz), which can penetrate about 15 cm inside the material. Because the change of the moisture content causes the change of the dielectric constant, which makes the electromagnetic field change, the moisture inside the material can be detected.

The NIR sensor emits near-infrared light of multiple wavelengths. The moisture content in the material has a certain proportional relationship with the amount of near-infrared light absorption of a specific wavelength, so it detects the moisture on the surface of the material and the shallow part of the material.

Typical application

★Food: grains, flour, soybeans, malt, rapeseed, corn, lentils, noodles, bean products, sugar, beet saccharification, beet flakes, candy, grain starch, coffee raw materials, food processing materials, fish meal, dry food, potato products , Potato flour, crumbs, flakes, seasoning powder, milk powder, spices, nuts, etc.

★Building materials: sand/gravel quartz powder, sand, bricks (raw materials), ceramics (raw materials), mortar, etc.

★Chemicals and pharmaceuticals: powder, granule, tablet, pill, flake fertilizer, phosphate, salt, potash, washing powder, polystyrene, foam plastic, synthetic material, PVC, acrylic paint, etc.

★Recycling: biomass, sludge, compost, etc.

★Others: wood shavings, sawdust, wood powder, calcium carbide slag, coal(pieces/powder), tobacco(shag/leaf), cast sand, glass, ceramics, coke, etc.

Features:

★It can store 6 calibration curves of different materials. When changing materials, directly replace the material curves without recalibration

★The capacitance field sensor can detect the average moisture inside the material

★Insensitive to the color and PH value of the material

★ Very high repeatability.

★High sensor protection level

★Maintenance-free sensor

★Optional high temperature (up to 130℃) sensor or explosion-proof sensor

Installation:

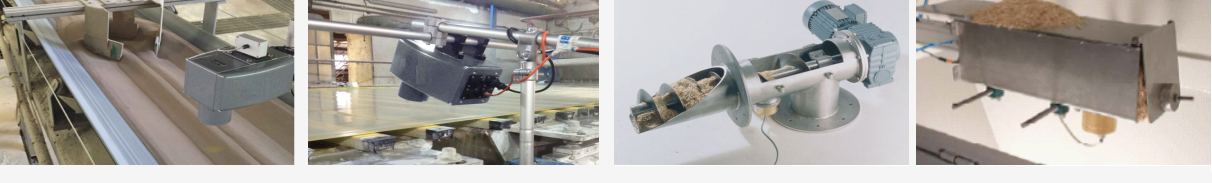

All Smart series smart bulk moisture sensors are dustproof, waterproof, shockproof and knockproof, and optional explosion-proof. The most typical installation positions of the sensor are inside the silo, on the silo wall, on the material conveying ramp, the upper or lower part of the conveyor belt, on the screw conveyor, and mixers and dryers.

Cases

★ Sludge water treatment, drying, wastewater and sludge process

★ Food (cereals, rice, flour, starch)

★ Salt products, mines

★ Potassium Chloride

★ Bulk Cargo Drying Plant

★ Ore processing

★ Energy/Coal

★ Sawdust, wood chips (granule products)

★ Porcelain products (granules and semi-finished products)

★ Clay processing

★ Kaolinit processing

★ REA-Gypsum products

★ concrete mixing plant

Controller features

• Quick and convenient

The navigation menu contains 6 languages, which can be operated easily.

• Process safety

4.3" or 7" large size color LCD touch screen, convenient and safe touch operation and debugging

Large size screen with red flashing alarm, clearly visible from long distances and in dark areas

Alarm immediately, safe the process

• Alarm event record

Real-time data curve display

Record function for up to 6000 alarms

• Expert calibration function

Can store 6 calibration curves of different materials

Multi-point calibration function up to 9 point

• Powerful self-diagnosis function

Built-in heartbeat monitoring function and watchdog

Monitor the status of controllers and sensors, and promptly remind customers to take necessary maintenance

High-standard hardware and software security and password protection

• Powerful control function

High(low) limit control function

Optional: Timer control(automatic cleaning) function

Optional: analog PID controller

Optional: PWM controller

• Flexible fieldbus communication functions for IOT4.0

Optional fieldbus MODBUS, HART, Foundation Fieldbus FF, PROFIBUS PA, PROFIBUS DP, etc.

Installation Examples

Measurement components and ranges

• H2O: 0~100%

Product datasheet: Bulk Moisture,SMART-MP ![]() , if you need more information, please contact us at sales@mzdd.de.

, if you need more information, please contact us at sales@mzdd.de.

Sintering moisture analyser, pellet moisture analyser, coal moisture analyser, calcium carbide slag moisture analyser, grain moisture analyser, starch moisture analyser, sludge moisture analyser, tobacco moisture analyser, tobacco leaf moisture analyser

Moisture Measuring,Biomass,Feeding stuff,Food & Beverage,Mineral products,Gypsum,Clay / Ceramics,Raw materials / Ores

Environment,Energy,Recycling,Foil / Tarp,Chemical / Pharmacy,Cocoa beans,Gypsum fiber boards,Limestone,Sewage sludge,Salt,Bricks & roof tiles,Wood chips,Apple pomace,Lignite ash,Sawdust,FGD-Gypsum,Iron ore,Coating foil,Slag sand